Do you want to achieve improvements in production, be efficient, and maximize performance and quality in your factory?

Para conseguir una mejora continua, es imprescindible medir. ¿Pero qué medimos? En este artículo destacamos qué valores cuantitativos son los más importantes medir, comparar y monitorear, desde un sistema MES, con el objetivo de conseguir mejoras y resultados en nuestra producción.

¿Qué es un KPI en producción?

Pero antes, vamos a aclarar qué es el KPI en producción, para poder definir así mejor nuestra estrategia.

Dentro de nuestro sistema, tenemos diferentes valores agrupados en métricas. Pero tenemos que definir desde nuestra estrategia, qué objetivos queremos conseguir y así, podremos definir qué KPIs son imprescindibles, los que serán nuestros indicadores clave de rendimiento.

Ejemplos de KPIs de producción:

A continuación, destacamos 10 ejemplos de KPIs de producción. Un KPI de producción debe ser:

- Estratégico, cuya finalidad sea alcanzar un objetivo

- Medible, debe ser cuantitativo

- Alcanzable, un objetivo real

* No obstante, consideramos que 10 KPIs, es un número factible para desarrollar un plan alcanzable. Así que más vale calidad que cantidad, y os aconsejamos que ajustéis KPIs alcanzables, medibles y alineados con vuestra estrategia, que os centréis en ellos para posteriormente poder poner el foco en el objetivo y conseguirlo.

Los 10 indicadores KPIs de producción para una mejora continua en industria según Geprom

What is a KPI in Production?

First, let’s clarify what a KPI in production is so we can better define our strategy.

Within our system, we have different values grouped into metrics. But we need to define from our strategy which objectives we want to achieve, and thus we can define which KPIs are essential – those that will be our key performance indicators.

Examples of Production KPIs:

Below we highlight 10 examples of production KPIs. A production KPI should be:

- Strategic: aimed at achieving an objective.

- Measurable: must be quantitative.

- Achievable: a realistic goal.

However, we consider that 10 KPIs is a feasible number to develop an achievable plan. Quality over quantity is preferred, so we recommend adjusting KPIs that are achievable, measurable, and aligned with your strategy, focusing on them to later concentrate on the objective and achieve it.

The 10 Production KPIs for Continuous Improvement in Industry according to Geprom

1 – OEE (Overall Equipment Effectiveness): Availability, Performance, and Quality

It is the key indicator to measure machine efficiency. It allows us to know the productivity and efficiency of the plant’s production processes. Likewise, it identifies aspects that are hindering productivity, such as stoppages, breakdowns, and quality issues.

-> How to calculate OEE?

-> Success Case

Other indicators can also be monitored, such as OOE (Overall Operation Effectiveness) or TEEP (Total Effective Equipment Performance).

TEEP takes into account a fourth factor, utilization. This indicator measures the effectiveness and efficiency of the equipment. A high value indicates optimal utilization and performance.

- Utilization = (Operating time / Available time) × 100

- TEEP = Availability × Performance × Quality × Utilization

OOE – Overall Operation Effectiveness: sums the metric of operational time per shift, measuring all operational management.

OEE = Performance × Availability × Quality

Availability = actual production time / activity time

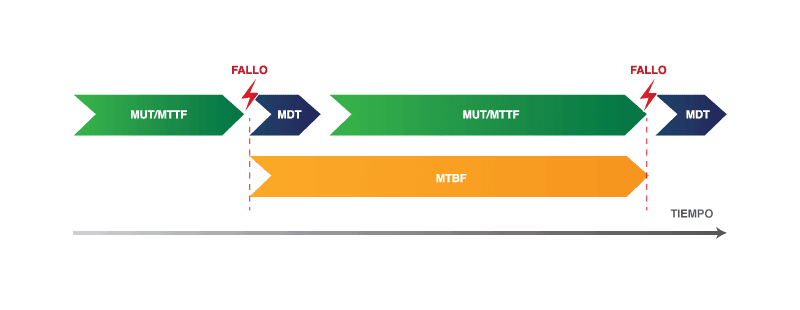

2 – MTBF (Mean Time Between Failures): Reliability

Time a machine operates correctly between two failures. This KPI helps understand the reliability of equipment and its failure rate.

- MTBF = (Total Available Time (TAT) – Total Lost Time (TLT)) / Number of Failures

TAT is considered the time the equipment is not in operation. This can be 24 hours or the period the equipment is running.

Other reliability indicators:

MDT (Mean Down Time – average downtime)

MTTF (Mean Time To Failure – before first failure)

MUT (Mean Up Time – after repair)

3 – MTTR – (Mean Time To Repair)

3 – MTTR (Mean Time To Repair)

Average time between a failure and its repair. It includes the time taken to diagnose the failure and restart the equipment.

- MTTR = Total maintenance time / Number of repairs

This KPI helps assess intervention effectiveness, work order evaluation, equipment maintenance capacity, and criteria such as technical documentation, accessibility, safety, manufacturer, and maintenance types.

An MES system can help monitor all strategic KPIs for your company. For a demo or more info, contact us directly.

4 – Downtime: Equipment Inactivity / Stoppage Rate

Unscheduled downtime. This KPI helps develop a preventive maintenance strategy to reduce unplanned stoppages.

5 – PMP (Planned Maintenance Percentage)

Measures efficiency and success in managing preventive maintenance in a company.

Two ways to calculate:

- Total hours spent on preventive maintenance / total maintenance hours

- Total hours spent on corrective maintenance / total maintenance hours

Multiply by 100 to get the percentage. The average is around 85% or higher.

6 – Maintenance Backlog

Shows the time needed to perform corrective, preventive, or predictive maintenance; quality inspections; improvements, etc. Provides visibility to measure team productivity.

- Total hours/man on planned, pending, scheduled, and executed tasks ÷ total available hours/man

7 – Production Cost per Unit (CPU)

Key KPI for market positioning and strategy, providing visibility on manufacturing system performance and optimizing production costs.

- CPU formula = (Direct material costs + Direct labor costs + Manufacturing overhead) / Units produced

-> Learn more about production management

8 – Work in Progress (WIP)

Shows which raw materials are being used in manufacturing, providing visibility to save costs, space, and production time.

- WIP = Manufacturing lead time × Production flow value

Also track discarded materials (scrap rate) to improve efficiency and sustainability.

9 – First Time Quality (FTQ)

Tracks the number of correctly finished pieces out of total produced.

10 – Delivery Time

Essential KPI in manufacturing and product sales, showing how long it takes to deliver an order from placement.

- Also measure OTIF (On Time In Full)

- OTIF formula = Number of perfect orders / Total orders

An MES system can help monitor all strategic KPIs for your company. For a demo or more info, contact us directly.

Other KPIs:

- Equipment availability

- Labor productivity index – SMED

…

An MES system can help monitor all strategic KPIs for your company. For a demo or more info, contact us directly.