Plastic injection molding is a widely used method in the manufacturing of various products, from household containers to parts for IoT devices. Although it is an efficient technique, it is not free from difficulties.

In this article, we will explore the challenges associated with the plastic injection molding production process and analyze some innovative solutions that the industry has developed to overcome these obstacles.

Plastic Injection: Common Concerns

1. Variability in Raw Material

Plastic, the essential base in this process, shows variations in its physical and chemical properties depending on the supplier and batch. This can generate inconsistencies in the quality of the final product. In addition, different resin blends are found, depending on their purity or recycling grade.

2. Extended Cycle Times

Long cycle times can affect production efficiency. The need for extended cooling times to avoid part deformation can be an issue, especially when aiming to increase production capacity.

3. Mold Wear

Molds used in the plastic injection process are exposed to extreme conditions, which can lead to wear over time. Their assembly in each injection machine must be precise and careful; otherwise, it could cause mold damage and lead to non-conforming parts. This wear not only impacts product quality but also increases maintenance costs and mold unavailability, limiting production.

4. Design Challenges

The design of parts for injection molding can be complex. Geometric complexity and the need to ensure uniform material distribution are constant challenges.

Innovative Solutions

What current technologies can help plastic injection companies overcome these problems? Below are some examples:

Advanced Process Control

The implementation of advanced control systems helps manage raw material variability. Sensors and online monitoring technologies, such as MES Systems, allow real-time adjustments to maintain consistent product quality.

Augmented Reality (AR) can also be used to provide real-time information on machinery status, facilitating preventive maintenance and quick troubleshooting.

Efficient Cooling Technologies

To address extended cycle times, more efficient cooling technologies are being adopted, such as high-speed water cooling systems and molds with optimized cooling channels. Within automation solutions, these techniques are proving highly cost-effective for the sector, making daily operations more efficient.

High-Durability Molding Materials

Developments in wear-resistant molding materials are helping extend mold lifespan. Advanced alloys and specialized coatings are being used to minimize wear and reduce the need for frequent replacements. This reduces mold maintenance and increases availability and service life.

Advanced Computer-Aided Design (CAD)

Advanced CAD tools allow designers to tackle the complexities associated with plastic injection molding. Digital process simulation helps predict potential issues and optimize part geometry before manufacturing.

Future (or Not-So-Future) Trends in Plastic Injection Molding

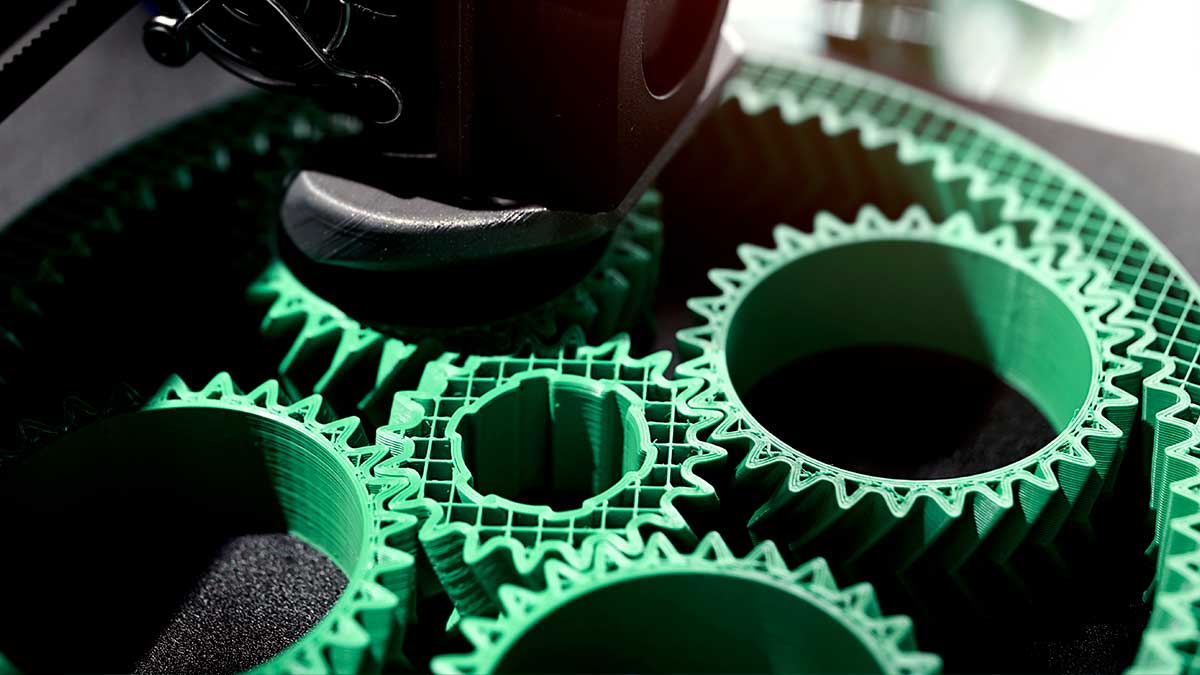

1. Additive Manufacturing of Molds

Additive manufacturing, such as 3D printing, is increasingly being used for mold creation. This not only reduces production costs but also facilitates the manufacturing of customized and complex molds.

2. Big Data and Advanced Analytics

The massive collection of data generated by machinery and production processes provides a unique opportunity for valuable insights. Applying big data techniques and advanced analytics enables pattern identification, trend forecasting, and informed decision-making. In the plastics sector, this translates into more efficient inventory management, more accurate production planning, and optimized supply chains.

3. Biodegradable and Sustainable Materials

Growing environmental awareness has led to the development of biodegradable and sustainable plastics. The adoption of these materials not only addresses environmental concerns but also positively influences consumer perception. Sustainability thus becomes one of the greatest challenges in the sector, as companies aim to manufacture the highest possible number of 100% recyclable products.

4. Cybersecurity

As plastic industry companies adopt Industry 4.0 enabling technologies, cybersecurity becomes a top concern. Protecting sensitive data and preventing cyberattacks are critical to ensuring the integrity and continuity of production processes. Implementing robust cybersecurity measures such as firewalls, encryption, and intrusion detection systems is essential to mitigating risks associated with digitalization.

The increasing demand for products manufactured through plastic injection means that the industry must address inherent challenges in the process. The future of this sector will be shaped by combining traditional techniques with emerging technologies. This will ensure a more resilient and environmentally friendly plastic injection molding process.

If you want information about innovative solutions for the plastics sector, contact us.

Te puede interesar:

· Sistema MES DCS / MES – Manufacturing Execution System

· Sistema de gestión de almacenes, SGA

· Gestión de mantenimiento por ordenador, GMAO

· Software de Eficiencia Energética