What are the advantages of analyzing data in industrial plants?

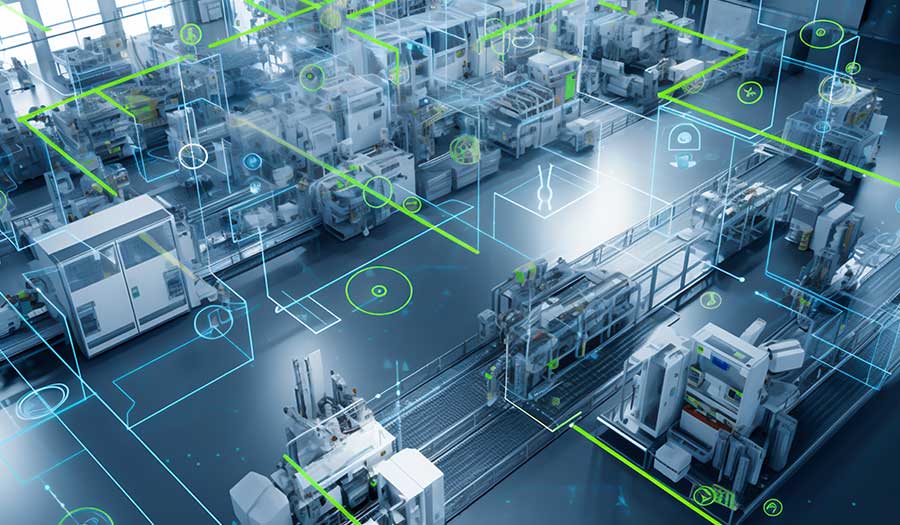

In the era of digital transformation, data analysis has become a strategic pillar for industrial plants. Thanks to technologies like IoT sensors, SCADA systems, artificial intelligence, and MES systems, factories generate and collect enormous volumes of data in real-time. But what are the concrete advantages of analyzing this data?

Below, we explore the main advantages of data analysis in industrial plants.

1. Improved Operational Efficiency

One of the most immediate benefits of data analysis in industrial plants is process optimization. By monitoring variables such as production speed, energy consumption, or downtime, you can identify bottlenecks, detect waste, and make evidence-based decisions to improve performance and, most importantly, increase productivity. For example, performance analytics allow for adjusting production parameters to maximize the efficiency of assembly lines or minimize energy consumption without compromising quality.

2. Anticipating Failures Before They Happen: Predictive Maintenance

Predictive maintenance, based on data analysis, allows you to anticipate failures before they occur. Through sensors that monitor equipment vibration, temperature, or pressure, it is possible to predict when a machine will need maintenance, avoiding costly downtime and extending the useful life of assets. For any industry, assets are very important, and keeping them operational for as long as possible is crucial. This approach, which is more advanced than traditional preventive maintenance, results in fewer unexpected shutdowns and greater facility availability.

3. Ensuring Product Quality

Quality control benefits enormously from data analysis. By monitoring critical variables in real-time—such as temperature, pressure, speed, or material mix—you can ensure that products meet required standards and quickly resolve any issues. Furthermore, by analyzing historical data, you can detect defect patterns, correlate them with specific production conditions, and take steps to correct them.

4. Cost Reduction

The ability to identify inefficiencies, minimize waste, prevent machine failures, and reduce resource consumption inevitably leads to a significant decrease in operational costs and consequently, directly affects the company’s bottom line. Data analysis allows companies to make smarter and faster decisions based on facts, not assumptions.

5. Traceability and Regulatory Compliance

The recording and analysis of industrial data also contributes to achieving environmental goals. It allows for measuring and reducing gas emissions, optimizing water and energy use, and ensuring compliance with environmental regulations. The historical recording and analysis of data facilitates batch traceability and compliance with regulatory standards (ISO, FDA, etc.), ensuring transparency and reliability in audits. This is key for companies seeking certifications like ISO 14001 or looking to reduce their carbon footprint.

6. Informed and Agile Decision-Making

Having dashboards, key performance indicators (KPIs), and automatically generated reports allows plant managers to make decisions based on real-time information. This not only improves organizational agility but also reduces the margin of error and enhances the ability to respond to unforeseen events or changes in demand. Objectivity in the control of the production process is indispensable. Data analysis in industrial plants enables more objective, efficient, and proactive management.

Conclusion: Data Analysis, a Strategic Necessity

Analyzing data in industrial plants is not just a technological option; it’s a competitive necessity. Organizations that integrate data analysis systems into their production processes gain clear benefits: more efficiency, lower costs, higher quality, fewer failures, and sustainability. In an increasingly complex and demanding industrial environment, data analysis is a key tool for driving innovation, profitability, and operational resilience.