What is a Master Production Schedule (MPS)?

A Master Production Schedule (MPS or PMP in Spanish) is the document that details the manufacturing plan of the references that we are going to produce in our factories within a given period of time. It is of great importance in the operations department of any productive company and needs to be nourished by different areas in order to be successfully executed.

With the MPS we can determine, through the different production or manufacturing orders (PO or MO), the specific volumes of each product that we are going to manufacture in the short term, generally on a weekly or biweekly basis, always taking the product’s manufacturing cycle as a minimum point. The MPS must consider the final product, available for shipment to the end customer, and detail the planning of sub-products or intermediate products.

How to create a Master Production Schedule (MPS)?

The Master Production Schedule usually falls under the operations management (or production management by default) and must contain the following elements:

1.- Demand in the short, medium and long term

Depending on the type of product we manufacture, the needs will be different. For example, perishable food products, whose shelf life is very short, will require continuous and short-term planning, while the production of a tool such as a hammer has a longer useful life and it is easier to work with safety stocks.

On the other hand, the sales department must be able to provide truthful and solid information that helps us have a vision over a given time frame, for example:

- Firm orders and delivery times.

- Orders with a high probability of entry also with their delivery dates.

- Historical information that allows us to make analogies with similar periods.

- Additional information that can be provided by the sales area, such as promotions, unusual circumstances or customer “feeling”.

With this demand analysis, we will already be able to determine the references that we have to deliver, their approximate quantity and with a product output schedule.

2.- Stocks of raw materials, auxiliary materials and finished product

The second step, which involves the logistics and supply areas, consists of determining the stock levels of finished product ready to be shipped to customers, raw materials, auxiliaries and intermediate products. With all this information we can determine the volume of references to be manufactured to meet orders and the possible safety stocks we have defined.

By involving the purchasing or supply department, we will be able to know, in case it is necessary to acquire volumes of raw material or auxiliary materials, the lead times to ensure that we can manufacture according to the established plan.

3.- Availability of lines and equipment

Our facilities have a production capacity that we know thanks to KPIs such as OEE obtained from an MES system or similar. Therefore, we know how much we can produce per unit of time. At this point, it is vital to involve the maintenance area, which, through a CMMS, has established preventive maintenance plans vital for the proper functioning of our facilities, so the knowledge of scheduled actions will determine the expected capacity once known.

It is also important to take into account the equipment available according to their work schedules. In many cases we have limitations such as certifications or specific training to operate certain machines that must be considered in the plan.

4.- Additional elements

In addition to taking into account sales forecasts, our stocks and the availability of our factory, we also need to consider other elements that, depending on our way of working or our sector, may be necessary, for example:

- Temporary quality department holds to ensure that the product is fit to be sent to the end customer.

- Minimum warehouse rest times required by a finished product.

- Maximum delivery times to the customer, for example, in products with an expiration date.

- Corporate strategies or priorities.

Once we have seen what a Master Production Schedule must include, it is time to execute it, but how do we do it?

From the MPS, the production department generates the different production orders and, in line with the planning area, which usually relies on advanced planning and scheduling (APS) tools, a sequenced and optimized production plan is generated that allows us to start working, and it will be the production area that executes the orders.

What benefits does a good Master Production Schedule provide?

- Detailed planning of needs and ability to meet them.

- Anticipating problems to prevent them from arising during plan execution (stoppages, stockouts, delivery failures).

- Meeting customer delivery dates and therefore their satisfaction.

- Improving stock levels of raw and auxiliary materials and finished products, to be more efficient and optimize time and space.

- Alignment between the different departments and collaboration to meet the company’s objectives.

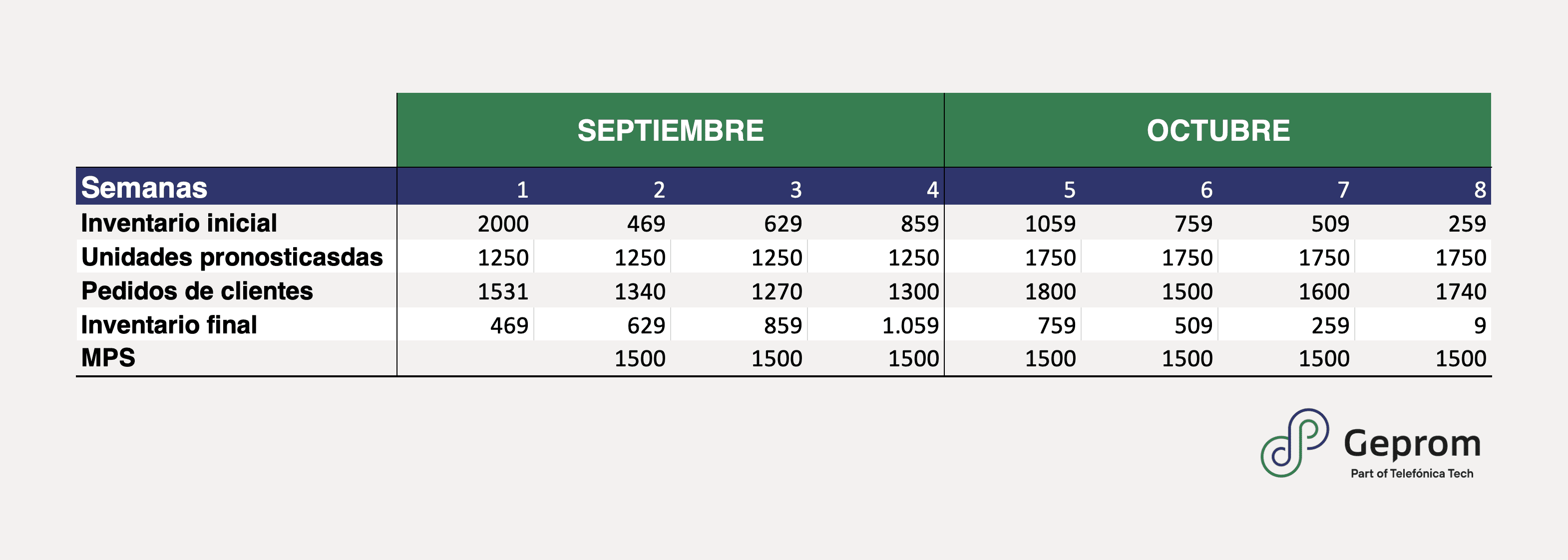

Example of a Master Production Schedule – MPS

We show a basic MPS exercise, based on a consumer goods company, focusing on product “x”. This company works with forecasts. Example with a data simulation:

- Initial inventory: 2,000 units

- Lot size: 1,500 units, referring to the number of units produced in each period.

- Demand forecast for September: 5,000 units

- Demand forecast for October: 7,000 units

This basic example shows forecast demand and orders.

- We always consider the higher value between forecast units and customer orders.

- If the initial inventory has a higher value than forecast or customer orders, MPS production will not be necessary.f we have software tools that help us with planning, monitoring and control of production processes, we will be able to monitor and adjust the master production schedule as necessary to deal with unforeseen events or demand changes. With the goal of optimizing, improving efficiency and reducing costs without altering product quality.