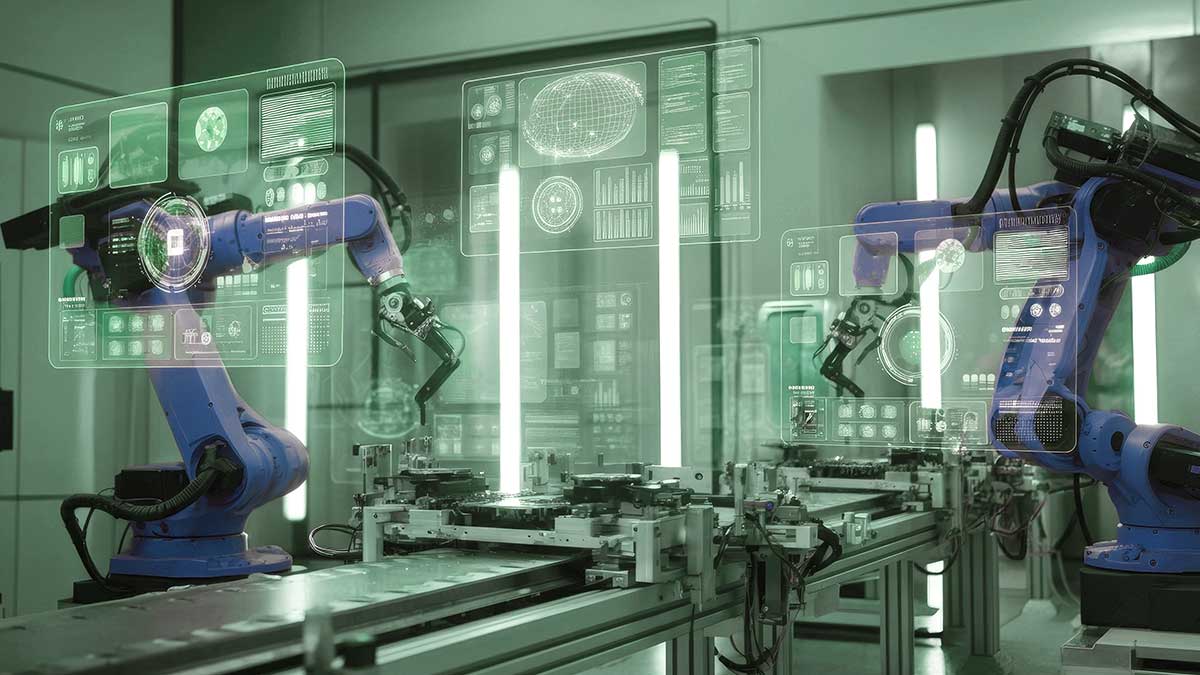

We Automate Complex Industrial Processes with Precision and Efficiency.

We design, integrate, and control technical processes such as painting, surface treatments, and environmental control, ensuring consistent quality and complete traceability.

What Solutions Does this Technology Include?

Geprom automates specific processes that require precision, repeatability, and extreme quality control:

TTS (Technical Surface Treatment)

Automation of pre-treatment of metal parts by washing, degreasing, and phosphating.

KTL (Kataphoretic Painting / Cathodic Electrodeposition)

Control of bath, load, and process to obtain uniform and resistant coatings.

Painting of Car Bodies or Industrial Parts

Integration of robotic painting booths, parameter regulation, and vision systems for validation.

Control and Air Conditioning of Process Booths

Management of temperature, humidity, and pressure to ensure optimal conditions.

Traceability of each Part in Real Time

Linking with RFID, vision, or MES systems for complete process tracking.

What Problems Does this Solution Solve?

Quality Variability Due to Manual or Poorly Calibrated Processes

With automated systems, we ensure constant and repeatable parameters, guaranteeing uniform quality in each part.

Losses of Product or Coating Due to Inefficient Dosing

Automated dosing optimizes the consumption of materials, reducing waste and ensuring maximum use of resources.

Contaminated or Poorly Air-Conditioned Environments that Affect the Finish

We control temperature, humidity, and air purity in real time to maintain stable conditions and obtain perfect finishes.

Difficulty Complying with Technical or Environmental Regulations

We integrate automatic controls that facilitate compliance with ISO, IATF standards, and environmental regulations from day one.

Lack of Traceability of the Treatment of each Part

Our systems record and link each stage of the process with the treated part, offering total and validated traceability in audits.

Benefits for your Company

-

Increased productivity

Automatic systems work 24/7 without pauses or fatigue.

Cycle time is reduced and overall performance is increased. -

Improved quality

Processes are more consistent and repeatable.

Human errors are minimized and constant quality is ensured. -

Reduction of operating costs

Less need for manual intervention.

Optimization of the use of materials, energy, and resources. -

Greater job security

Dangerous or repetitive tasks are taken over by machines.

The risk of accidents and occupational diseases is reduced. -

Total traceability

Each stage of the process is automatically recorded.

Improves the capacity for analysis, auditing, and regulatory compliance. -

Flexibility and scalability

Automated systems can adapt to new products or volumes. It is easier to implement improvements or expansions.

-

Real-time control

Supervision and immediate adjustments thanks to sensors, PLCs, and software. Rapid reaction to deviations or failures.

-

Waste reduction

Greater precision in dosing, cutting, assembly, etc.

Improved use of raw materials.

Optimize your industrial processes with precision and total traceability

Talk to an expertUse Cases

At Geprom, we have integrated control systems in real industrial environments, adapted to the challenges of each sector. Here are some application examples:

Automotive

KTL and robotic painting of car bodies

Aeronautics

Thermal and surface treatments with traceability

Metallurgy

Controlled coatings and galvanizing

Appliances and Consumer Goods

Finish quality in paint or lacquer

Success Stories

What our Clients Say

Methodology

How Do We Work?

Analysis of your Current Process and Quality Requirements

We evaluate your starting situation to define objectives and quality standards.

Design of the Automation and Sensorization System

We create a customized solution incorporating the necessary sensors for each process.

Integration of control, vision, traceability, and air conditioning

We connect all systems to ensure precision, safety, and optimal conditions.

Parameter Validation and Start-Up

We test and adjust each stage until we ensure consistent and reliable results.

Support, Maintenance, and Process Evolution

We accompany your plant with technical support and continuous improvements in the long term.

Get your Questions Answered

Frequently Asked Questions

Yes. We adapt the solution to your sector-specific regulatory requirements.

Yes. We analyze your facilities and design integrable solutions.

From partial control (dosing, ventilation) to complete automation with robots, sensors, and traceability.

Still Have Doubts?

Still have questions? Contact us and our team will be happy to help.