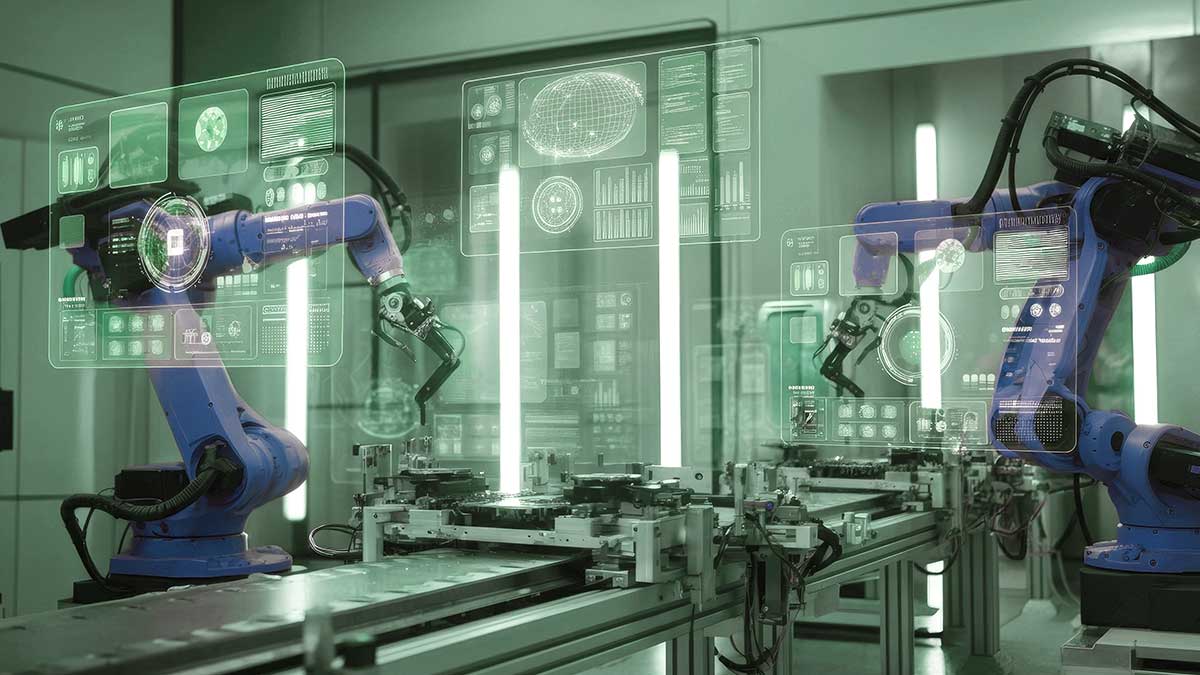

OT Networks: Secure Infrastructure for Industrial Automation

Robust and reliable industrial connectivity that enables digital transformation in production environments.

What Solutions Does this Technology Include?

OT Network Architectures

Design according to the Purdue model and IEC 62443 to guarantee segmentation, resilience, and scalability.

IT/OT Convergence

Secure integration between IT and OT networks to facilitate digital and operational convergence.

Implementation of SCADA and PLC Systems

Deployment of SCADA, PLC, DCS, gateways, and IoT sensors with real-time communication.

Industrial Cybersecurity

Auditing, segmentation, access control, monitoring, and incident response.

OT Managed Services

Outsourcing and managed support for high availability and constant technological updating.

Challenges We Solve

Challenges

-

Security risks inherent to legacy devices and unencrypted industrial protocols (Modbus, Profibus, OPC‑DA, etc.)

-

Poor integration between IT and OT, which creates information silos and reduces operational efficiency

-

Lack of visibility and continuous monitoring that hinders the early detection of cyber incidents

-

Absence of segmentation, robust authentication, and cybersecurity policies adapted to industrial environments

Benefits

-

High Availability and Reliability: designed for demanding production environments with fault tolerance.

-

Improved cybersecurity: adoption of IEC 62443 standards and segmented architecture to minimize risks

-

Real-time monitoring and anomaly detection with automated responses.

-

Integrated OT management that facilitates data analysis, predictive maintenance, traceability, and digitized decision-making

-

Flexibility and scalability: the infrastructure allows adapting to new assets and increasing automation with operational efficiency.

Protect your OT network with cybersecurity, visibility, and high availability

Talk to an expertUse Cases

Manufacturing / Automotive

Autonomous production, robot integration, digital twins for simulation and optimization

Energy / Utilities

Control and monitoring of power plants, gas, water, refineries

Agribusiness / Agriculture

Irrigation automation, humidity and climate sensors, IIoT systems to optimize resources

Construction / Smart Buildings

Supervision of air conditioning, lighting, security, and intelligent energy management

Success Stories

What our Clients Say

Get your Questions Answered

Frequently Asked Questions

It is reflected in reduced downtime, optimized maintenance, lower risk of security incidents, improved energy efficiency, and increased operational productivity.

Through industrial gateways that translate traditional protocols (Modbus, Profibus, OPC, etc.) to TCP/IP secure and segmented environments.

Yes. Frameworks such as

Through robust authentication, network segmentation, role-based access control (RBAC), protocol encryption when applicable, and continuous monitoring with incident response.

Still Have Doubts?

Still have questions? Contact us and our team will be happy to help.