What is a waste? How does it affect my production process?

A waste, in the context of industrial production processes, is any task that does not add value or generate a benefit or improvement in the process — in other words, it is waste.

Its history goes back to the 1950s and 1960s, within the Lean Manufacturing philosophy (known at the time as the “Toyota Production System”), developed by the Japanese automotive company Toyota.

The aim of this research was to eliminate waste in order to improve processes and become more efficient in managing and producing. This arose from the need to find efficient ways of producing cars after World War II, when resources were scarce.

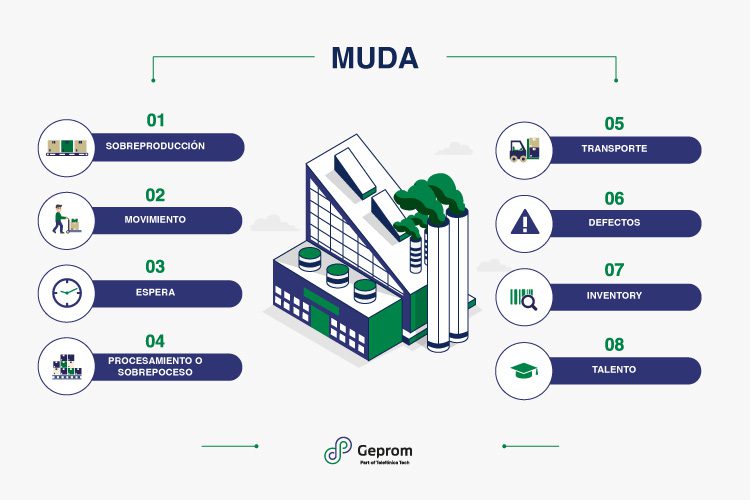

Thus, Muda is one of the key aspects of this philosophy, as it focuses on identifying and eliminating all tasks that do not add value to production processes, achieving greater efficiency and reducing costs.

What are the main types of wastes?

Historically, 5 were identified, but over time more have been added and the list has been updated.

Overproduction Waste: Considered the worst of all. This occurs when more products or services are produced than the customer needs or requests. Eliminating overproduction is crucial to avoid unnecessary inventory build-up and the associated costs, as resources are spent managing undemanded products such as space, staff, movement, and materials.

Motion Waste: Happens when unnecessary movements are performed that do not add value to the product. This may be due to poor organization, incorrect planning, or mismanagement of staff on the line.

Waiting Waste: As the name suggests, it is the waiting of people, machines, or materials to continue with their task. Reducing this idle time is vital to maintaining a more efficient workflow.

Overprocessing Waste: Actions performed repeatedly or unnecessarily on a process without adding value to the end customer. Example: Packaging a product that will be unpacked in the next step.

Transportation Waste: Moving material or product without adding any value. It is important to analyze workflows, quantities, and frequencies to achieve optimal transport.

Defects Waste: Defects and errors are inherently waste. They add no value and generate multiple kinds of losses: cost of defective material, repair or management time, reprocessing, etc.

Inventory Waste: Related to overproduction, it refers to wasted space due to excessive storage of materials, work in progress, or finished products. Reducing excess inventory helps lower storage costs and improve production flexibility.

Unused Talent: Not making use of employees’ experience, knowledge, and creativity.

This is why Lean Manufacturing focuses on reducing these quality failures and detecting them early.

At Geprom Part of Telefónica Tech, we help you implement solutions to identify, control, and minimize these wastes in your manufacturing processes, thus optimizing efficiency and quality.

You may also be interested in:

Consultoría industrial especializada en transformación digital