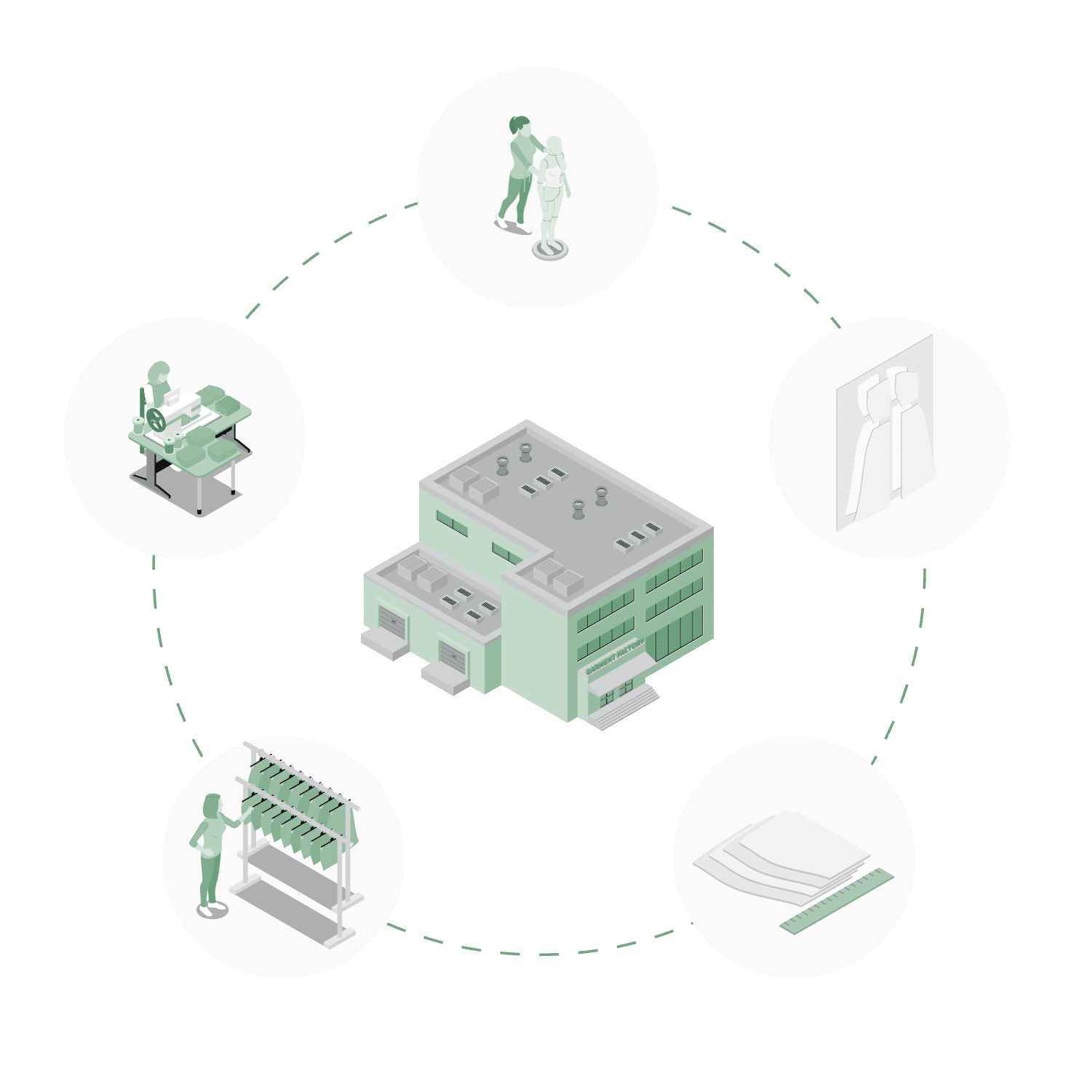

In the current textile industry, technology has become a key ally for maintaining competitiveness and ensuring operational efficiency. MES (Manufacturing Execution System) software is an essential tool that allows for the real-time management and optimization of production, providing accurate data for strategic decision-making. This MES system not only ensures greater efficiency in production processes but also helps textile companies adapt to the demands of sustainability and digitalization imposed by Industry 4.0.

Optimizing Textile Production with an MES System

The MES centralizes all data obtained during production, improving responsiveness and efficiency at every stage of the process.

By collecting real-time information from machines and operators, it is possible to:

- Monitor and adjust processes immediately, avoiding wasted time and resources.

- Better coordinate teams and operations, optimizing workflow between different departments of the factory.

Thanks to the implementation of an MES system, managers can supervise production more efficiently, adjusting resources according to the specific needs of each manufacturing line.

Benefits of Implementing an MES System in Your Textile Company

Real-Time Control and Planning: Key in Textile Production

In the textile industry, planning and control capabilities are essential to meet delivery deadlines and maximize productivity.

MES allows production orders to be managed automatically, ensuring that all stages of the process are aligned with the company’s objectives.

A particularly important feature in this sector is the ability to group and ungroup work orders according to process routes. For example, in dyeing, multiple orders are often grouped together to optimize time and materials used.

This system not only facilitates production planning but also offers detailed inventory control, managing both raw materials and finished products. This is essential for avoiding delays or interruptions in the supply chain.

Improved Efficiency and Cost Reduction in the Textile Industry

One of the most outstanding benefits of MES software is the ability to improve operational efficiency and reduce production costs.

By integrating continuous monitoring of machine performance, the system allows for:

- Identifying critical points that affect productivity.

- Optimizing the use of available resources.

- Controlling process variables such as thickness, length, width, and weight.

- Reducing the consumption of energy and materials, contributing to sustainability and minimizing environmental impact.

In our experience, the ability to access real-time data on the performance of each machine has allowed for more informed decision-making, which translates into lower costs and better profitability.

Sustainability in the Textile Industry Thanks to MES Software

Sustainability is one of the fundamental pillars of Industry 4.0 and, in the textile sector, the implementation of MES software has proven to be a key tool for achieving environmental goals. This system allows for:

- Optimizing the consumption of resources such as water, energy, and chemicals used in production.

- Reducing waste generated during manufacturing processes.

- Facilitating the traceability of products, ensuring that each stage of the process complies with sustainability standards.

In summary, the use of an MES system not only improves operational efficiency but also helps reduce the ecological footprint of textile factories, an aspect increasingly valued by customers and international regulations.

Performance Measurement (OEE) and Traceability in Textile Production

The calculation of OEE (Overall Equipment Effectiveness) is crucial for measuring the overall performance of machinery on the factory floor. With MES software, it is possible to:

- Monitor the availability and productivity of each machine.

- Improve the efficiency of production processes by identifying areas for improvement.

- Ensure complete product traceability, from raw materials to the final product.

Traceability is especially important in the textile industry, where the quality of the final product and compliance with sustainability regulations are essential aspects for competing in the global market.

An MES system ensures that these requirements are met effectively, reducing errors and improving customer satisfaction.

Integration and Automation of Textile Processes with an MES System

In the textile industry, the interconnection and automation of processes are fundamental for achieving efficient and scalable production.

MES software allows for the integration of all plant systems and operations into a single platform, which facilitates:

- The automation of key processes, such as weaving, dyeing, and finishing.

- The centralization of information, eliminating the duplication of tasks and ensuring that all data is updated in real-time.

- An agile response to changes in demand or customer specifications, without compromising delivery times.

Thanks to this integration, textile companies can increase their flexibility, reduce errors, and improve their responsiveness in a constantly changing market.

Practical Example

A textile factory that produces clothing can use an MES to:

- Track the inventory of dyed fabrics in real-time.

- Adjust the clothing lines based on customer demand.

- Monitor the quality of dyeing in real-time.

- Ensure that final products comply with environmental and sustainability standards thanks to instant control of the entire process.

In summary, an MES system not only improves the operational efficiency of a textile factory but also helps meet market demands and regulations, maintaining competitiveness in a dynamic environment.

If you would like information about an MES system, contact us:

You might be interested in:

· What is OEE Analysis in a Company

· 10 Production KPIs to Drive Continuous Improvement in the Factory

· MES System DCS / MES – Manufacturing Execution System

· Energy Efficiency Software