CMMS – Computerized Maintenance Management System

Centralize all maintenance information in a single database.

Optimize your Plant with Complete Visibility and Total Maintenance Control

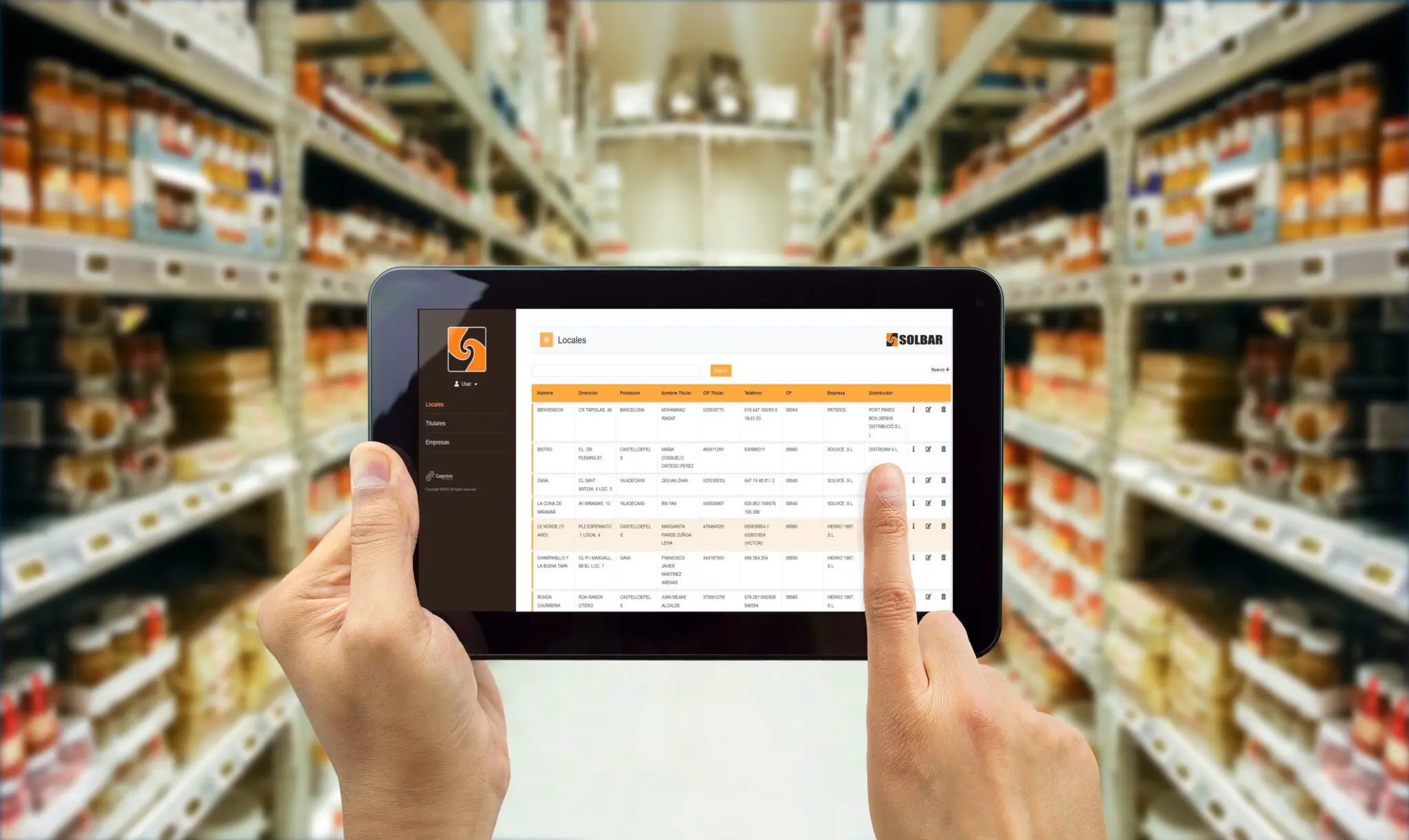

CMMS (Computerized Maintenance Management System) maintenance software is a tool designed to comprehensively plan, control, and manage all operations of the maintenance department.

It facilitates dynamic management and efficient real-time decision-making, optimizing tasks, resources, and assets, and helping to reduce unforeseen breakdowns and unscheduled downtime. It allows you to centralize all critical maintenance information: work orders, equipment, spare parts, incidents, technicians, suppliers, and subcontracted services, from a single digital platform.

Knowing the degree of maintenance required for the facilities allows the development of appropriate plans to control operations. The system easily adapts to connected industrial environments, enabling direct linking with assets to activate maintenance tasks according to operating conditions.

All generated data is visualized through reports with fully editable and customizable graphs and statistics in real time, which facilitates agile decision-making based on reliable and updated data.

To take maintenance a step further, the system is fully compatible with predictive technologies and advanced analytics. From Geprom, these technologies can be integrated into the CMMS to complete the maintenance plan with preventive, corrective, and predictive strategies.

Main Functions of the CMMS System

Real-time Asset Management

Monitor sensors, machines, robots, and energy consumption from a centralized and connected platform.

Automatic Maintenance Planning

Generate preventive and corrective maintenance with dynamic assignment to internal technicians and subcontractors.

Digitization of Tasks and Orders

Digitize tasks, work orders, and checklists on mobile devices or panels on the plant floor.

Centralized Document Manager

Organize manuals, job instructions, forms, and reports accessible from the work environment.

Spare Parts Inventory Control

Manage entries, exits, locations, and stock of materials linked to maintenance

Connection with Sensors and Equipment

Collect real metrics from connected assets to improve planning and analysis.

KPIs and Personalized Reports

Consult key indicators such as OEE, costs, and productivity in real time and with flexible visualization.

Integration with Industrial Systems

Connect the CMMS with MES, ERP, WMS, RFID, NFC, scales, and plant IoT devices.

Benefits of the CMMS System

- Reduce operating and maintenance management costs.

- Increase the lifespan and productivity of assets.

- Reduce failures, repairs, breakdowns, and downtime.

- Improve inventory management.

- Increase the efficiency and safety of personnel.

- Secure and reliable data in real time for the entire department.

- Digitize document management and reduce paper use in the factory.

- System prepared to incorporate advanced analytics and predictive maintenance.

- Standardize and approve maintenance tasks.

Reduce downtime and improve the efficiency of your maintenance

Talk to an expertUse Cases

Automated Maintenance Planning

Schedule preventive maintenance to avoid failures and prolong the lifespan of equipment.

Real-time Visibility and Control

Monitor the status of assets and progress of tasks for more agile and reliable management.

Dynamic Resource Coordination

Quickly assign jobs to internal teams and subcontractors, optimizing time and costs.

Complete Process Digitization

Manage orders, checklists, and documentation digitally to reduce errors and administrative time.

Related Solutions and Services

Success Stories

What our Clients Say

The Digital Maturity Pyramid

What Level of Digital Maturity Does your Maintenance Have?

The evolution towards excellent maintenance occurs in stages. Based on the ISA-95 model, this pyramid helps you understand how factory systems are connected from basic automation to integrated platforms.

Level 3 is the turning point: with a CMMS you gain total control of the maintenance cycle, reduction of unplanned downtime, spare parts management, order traceability, and real-time visibility to make decisions with data. From here it is easy to scale towards CBM, MOM integration and predictive.

Do you want to explore how to adapt a CMMS to your reality?

Talk to our experts and take your plant’s maintenance to the next level.

Get your Questions Answered

Frequently Asked Questions

Geprom’s approach combines an intuitive interface and a progressive training plan for key users and technicians, with support during implementation. Early team involvement reduces cultural barriers and accelerates adoption.

In addition to historical records, CMMS offers reports and advanced analytics to detect patterns, cost drivers, and optimization opportunities. It enables data-driven decisions (MTBF, MTTR, OEE, costs) and continuous improvement plans.

Geprom’s CMMS prioritizes work orders based on criticality, urgency, impact on production, and availability of personnel/spare parts. This allows the team to focus on what is essential, avoiding overloads and reducing time and costs.

By combining sensor data with predictive models, the CMMS anticipates failures and schedules interventions before breakdowns occur. It improves equipment availability, reduces unplanned shutdowns, and optimizes maintenance resources.

Still Have Doubts?

Still have questions? Contact us and our team will be happy to help.