Industrial Predictive Maintenance

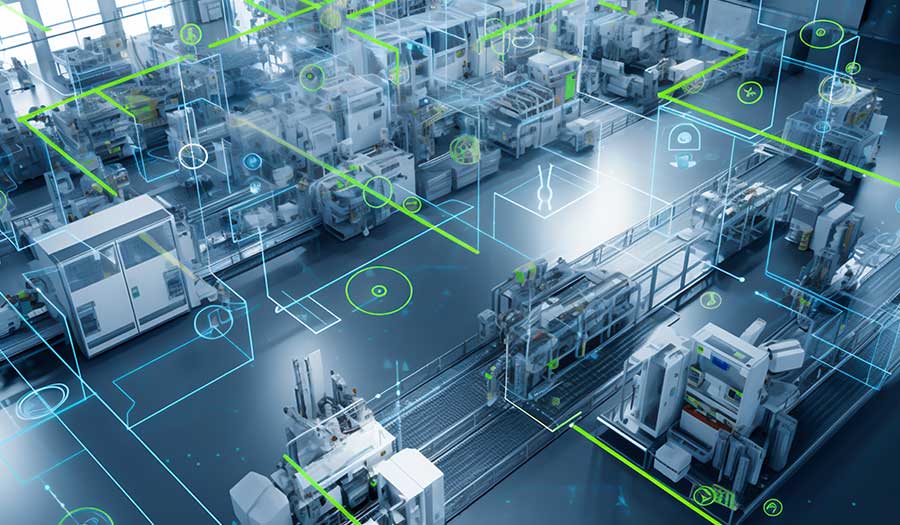

Anticipate failures and maximize the reliability of your facilities with real-time data.

What is Industrial Predictive Maintenance?

Predictive maintenance has become a fundamental pillar of Industry 4.0, making it possible to detect failures before they occur thanks to advanced analysis of industrial data. Improve the availability of your assets, reduce operating costs, and optimize intervention planning with a strategy based on real data.

Main Functions

Real-time Monitoring of Condition Sensors

Continuous capture of data (vibration, temperature, ultrasound, current, wear particles) through IoT sensors installed in critical equipment.

Intelligent Industrial Data Collection

Automated and continuous collection of key variables (vibrations, temperature, cycles, consumption, etc.) from multiple sources: IoT sensors, SCADA, MES, and PLCs. This robust database allows building a reliable technical history of each piece of equipment.

Advanced Analysis with AI and Predictive Models

Application of machine learning algorithms and statistical analysis to detect hidden patterns, deviations, or symptoms of failure. Breakdowns, quality defects, or loss of performance are anticipated.

Technical Pilot and Scalable Deployment

Initial implementation in a controlled environment (pilot test) that validates technical feasibility, evaluates available sensors, and defines the roadmap for scaling to the rest of the lines or plants.

Real-time Visualization and Reporting

Dashboards adapted to different profiles (maintenance, production, management) with KPIs such as asset status, alerts, failure predictions, and recommendations. Integration with CMMS for automatic orders.

Early Activation of Alerts and Interventions

Issuance of intelligent alerts before a critical failure occurs. The system recommends preventive actions or automatically generates work orders, reducing intervention costs and downtime.

Challenges We Solve

Challenges

-

Does your factory suffer unexpected stoppages that slow down production and drive up costs?

-

Do you still do reactive maintenance, without knowing when a critical machine may fail?

-

Is it difficult for you to justify the expense of spare parts or the replacement of components ahead of time?

-

Don’t you know where to start to implement a maintenance 4.0 strategy?

Predictive maintenance allows you to anticipate failures before they occur, extending the useful life of your assets, reducing stoppages, and optimizing operating costs.

Benefits

-

Improved overall reliability

-

Reduction of the annual intervention rate

-

Improved safety and reduction of accidents

-

Decrease in spending on spare parts

-

Optimization of the life cycle cost of assets

-

Reduction of serious failures thanks to the continuous use of data

Anticipate critical failures with predictive maintenance

Talk to an expertRelated Solutions and Services

Success Stories

What our Clients Say

The Digital Maturity Pyramid

What Level of Digital Maturity Does this Product Cover?

Geprom’s Industrial Predictive Maintenance is located in Level 5 of the Digital Maturity Pyramid (ISA-95).

At this level, organizations advance from operational digitization (continuous capture and visualization of equipment condition data) to integrated production management, where real-time data is combined with predictive algorithms to anticipate failures and optimize maintenance planning.

This level implies:

- Continuous capture of critical variables (vibration, temperature, cycles, consumption, etc.) from IoT sensors, SCADA, MES or PLCs.

- Early identification of patterns and anomalies using Machine Learning models.

- Generation of automatic alerts and recommendations to intervene before a failure occurs.

- Integration with CMMS and MES systems for the automatic creation of work orders and improvement of operational efficiency.

Still Have Questions?

Still have questions? Contact us and our team will be happy to help.