QMS – Advanced Quality Management Software

Boost your production with a platform that integrates all quality processes into a single platform for flexible, safe, and efficient production.

What is Quality Management Software?

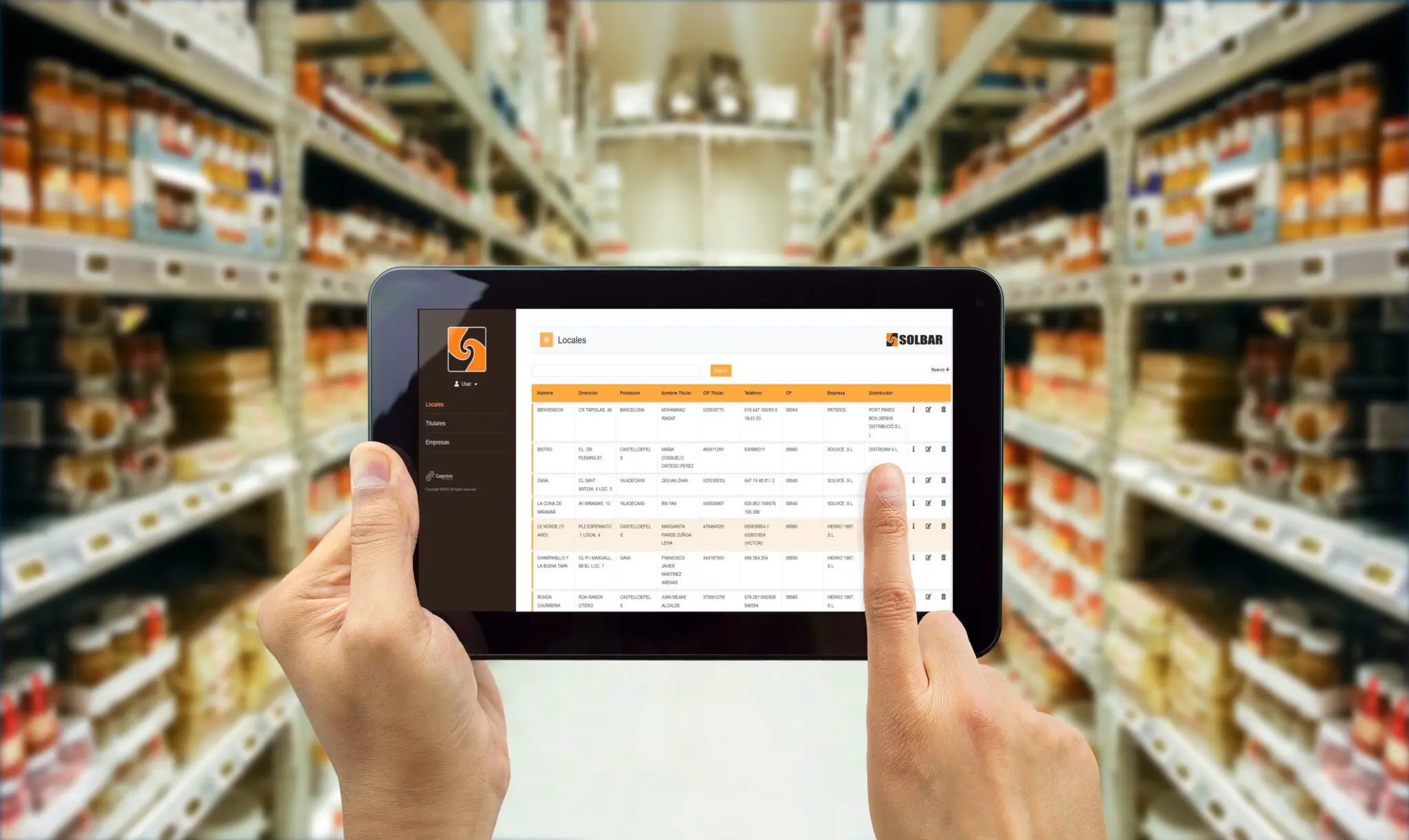

Quality Management Software (QMS) is a comprehensive platform designed for the advanced management, control, and planning of quality processes, facilitating complete process traceability and thorough compliance with audit and certification requirements.

It focuses specifically on the processes and data relevant to quality in the production environment to identify defects in a timely manner and sustainably improve quality.

With QMS software, you can maximize product quality in all phases of the value chain, from raw material input to final product output, improving real-time decision-making.

Main Functions of Quality Software

Integration of quality control tools (APQP, FMEA, PPAP, HACCP/APPCC) on a single platform

Management of alerts and non-conformities, with support for 8D reports and statistical process control (SPC)

Digitization of processes and regulatory compliance, eliminating paper and facilitating compliance with ISO and FDA 21 CFR Part 11 standards.

Complete traceability and real-time control of materials, batches, and data, with integration to LIMS, ERP, and MES.

Real-time visualization and reporting, including dashboards and analysis to improve decision-making.

Specific quality management for complex industrial processes, such as car body assembly, welding, dimensional control, and data acquisition via sensors, artificial vision, scales, etc.

Benefits of Advanced Quality Management Software

-

Guaranteed total traceability of processes.

-

Real-time reporting and comprehensive process analysis.

-

Optimize processes and achieve ROI from the early stages of implementation.

-

Maximum integration on the same platform with other systems, resources, and machines.

-

Digitization of factory processes and elimination of paper.

-

Recognition for regulatory compliance and process reliability.

-

Reduces testing costs by up to 75%.

-

AI-powered recommendation engine.

Integrate traceability, compliance, and AI into a single platform

Talk to an expertUse Cases

Centralized Integration of Quality Processes

Integrate quality management processes, tasks, and data into a single planning and control solution, improving traceability, regulatory compliance, and operational efficiency throughout the plant.

Quality Planning

Define control plans and inspection strategies from the initial phase, ensuring early risk detection and standardization of procedures.

Reception and Data Acquisition

Digitize data capture in goods receipt and in the different production phases, ensuring that all records are valid and comparable in any system or machine.

Real-time Analysis and Reports

Turn quality data into actionable insights through dynamic dashboards and reports that facilitate decision-making and audit compliance.

Related Solutions and Services

Success Stories

What our Clients Say

The Digital Maturity Pyramid

What Level of Digital Maturity Does your Quality Management Have?

The evolution towards excellent quality management occurs in stages. Based on the ISA-95 model, this pyramid helps to understand how to advance from basic digitization to an integral quality ecosystem connected to the entire plant.

Level 3 is the key point: with a QMS you get total traceability, regulatory compliance, and real-time visibility to decide with reliable data.

From here it is easy to scale towards MOM integration and predictive quality with AI.

Do you want to explore how to adapt a QMS to your reality?

Talk to our experts and take the quality of your production to the next level.

Get your Questions Answered

Frequently Asked Questions

Geprom’s QMS centralizes all documentation, procedures, and quality records, facilitating traceability and report preparation for audits, ensuring compliance with regulations such as ISO 9001 and other international regulations.

The entire value chain: customers, employees, and suppliers. Benefits include less waste, reduced quality and compliance costs, early defect detection, greater satisfaction, and better decision-making.

A QMS should be modular and adaptable, including quality planning, measurement data management, SPC, traceability, document management, equipment management, laboratory management, and complaint management.

It integrates data from IT and OT systems throughout the value chain to plan and control quality, detect problems early, reduce costs, and document all knowledge for audits and continuous improvement.

Still Have Doubts?

Still have questions? Contact us and our team will be happy to help.