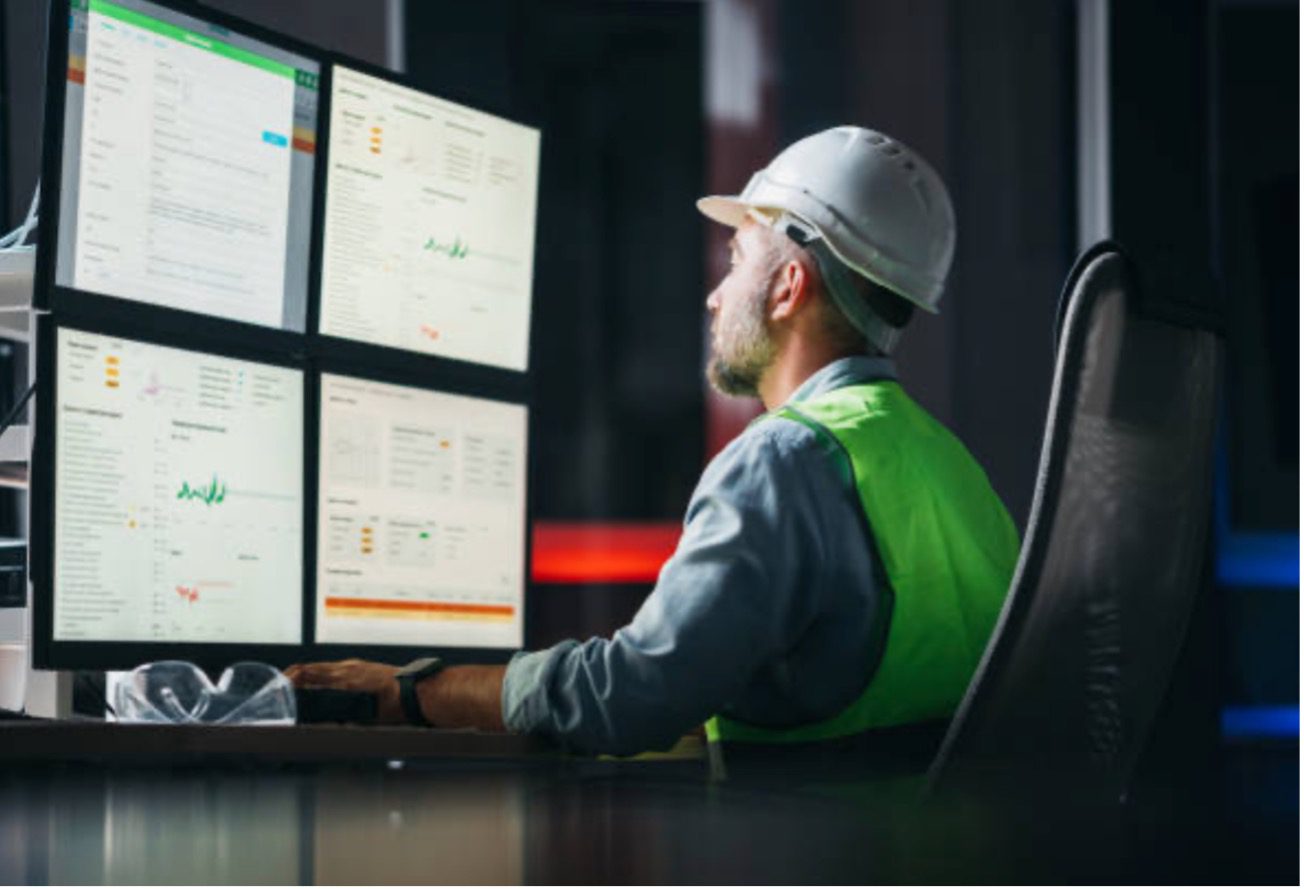

SCADA System – Supervisory Control and Data Acquisition

Supervision, collection, and control of data in real time.

What is a SCADA System?

A SCADA (Supervisory Control and Data Acquisition) system allows you to monitor and control industrial processes in real time, offering complete visibility of machines, production lines, auxiliary systems, and key parameters for operation.

At Geprom, we offer open, scalable SCADA platforms that are prepared to integrate with automation, MES, maintenance, and energy efficiency systems.

With a modern SCADA, you don’t just control. You make decisions faster, reduce errors, anticipate failures, and transform data into productivity.

Main Functionalities of the SCADA System

Real-time Supervision

Dynamic visualization of processes, alarms, variables, and operating states from any device.

Remote Process Control

Allows you to act on equipment and systems directly from the SCADA environment, securely and traceably.

Advanced Alarm Management

Flexible configuration of alarms, notifications, and prioritization of critical events.

Data History and Traceability

Recording of trends, events, and values for later analysis and data-driven decision making.

Intuitive Graphical Interface

Customizable visual environments with navigation by plant, machine, or process.

Dashboards and Performance Indicators

Monitoring of operational KPIs (cycle times, consumption, efficiency) integrated into the SCADA.

Security and Access Control

Management of users, permissions, and traceability of actions to ensure safe operation.

Integration with PLCs, Sensors, and IT/OT

Native connectivity with PLCs, industrial sensors, and business systems (MES, ERP, etc.).

Benefits of the SCADA System

-

Total process visibility

Centralizes information from all your machines, lines, or production areas.

-

Immediate response to incidents

Detect, analyze, and act in real time to any anomaly.

-

Data-driven decision making

Turns technical information into useful knowledge with dashboards and integrated analytics.

-

Fewer stops, more productivity

Anticipate problems with history logs, smart alarms, and predictive maintenance.

-

Remote and secure access

Monitor and control your facilities from any location, with encrypted and controlled access.

-

Intuitive and customizable environment

Design custom screens according to the roles and needs of each team.

-

Prepared for industry 4.0.

Connectivity with IoT, MES, Historian, advanced analytics, and artificial intelligence.

Discover how to improve your operational efficiency

Talk to an expertUse Cases

Production Lines with Multiple Stations

Visualize and synchronize distributed processes, detect bottlenecks, and improve workflow.

Plants with High Availability Needs

Implement redundancy, backup, and recovery to ensure operational continuity.

Processes with High Sensitivity to Parameters

Real-time control and alarms for out-of-range conditions.

Industry with Demanding Regulations

Record and document each variable and action for traceability and audits (food, pharma, automotive, etc.).

Related Solutions and Services

Success Stories

What our Clients Say

The Digital Maturity Pyramid

What Level of Digital Maturity Does SCADA Cover in your Plant?

Digital transformation in industry is a structured process that progresses in phases. Within our digital maturity pyramid, based on the ISA-95 model, SCADA systems represent a key intermediate level: they allow moving from simple data capture to real-time supervision and control of the plant.

Level 2 corresponds to advanced Operational Digitization: thanks to a SCADA, companies integrate process monitoring, alarms, history logs, and remote machinery control, obtaining complete visibility of the operation. This layer connects automation systems with the upper management level (MES, ERP…), enabling traceability, efficiency, and immediate data-driven decisions.

It is at this point where organizations leave behind manual and fragmented operation, and begin to work with a centralized and secure vision of the entire plant.

Do you want to explore how a SCADA can transform the supervision of your plant?

Talk to our experts and take control of your plant to the next level.

Get your Questions Answered

Frequently Asked Questions

Absolutely. The SCADA environment allows you to create dashboards, alarms, and customized views per profile, so that each user only has the information they need, in a clear and operational manner.

Yes. The solution allows secure, encrypted remote access with user control. You will be able to view, monitor, and, if authorized, take action from a PC, tablet, or smartphone.

Yes. The architecture is scalable: you can start with one line or process and then connect the entire plant or multiple locations.

It enables early fault detection, remote control, energy savings, and improved decision-making through real-time data and historical records.

Still Have Doubts?

Still have questions? Contact us and our team will be happy to help.