An MES system, “Manufacturing Execution System,” is software that allows monitoring, controlling, and recording production process operations in real time.

Currently, incorporating this software in industry is becoming essential and is undoubtedly one of the central technological tools for digital transformation. These platforms have proven their importance as they increase productivity and efficiency while reducing costs and ensuring traceability of the production process.

MES as the Core of Industry 4.0

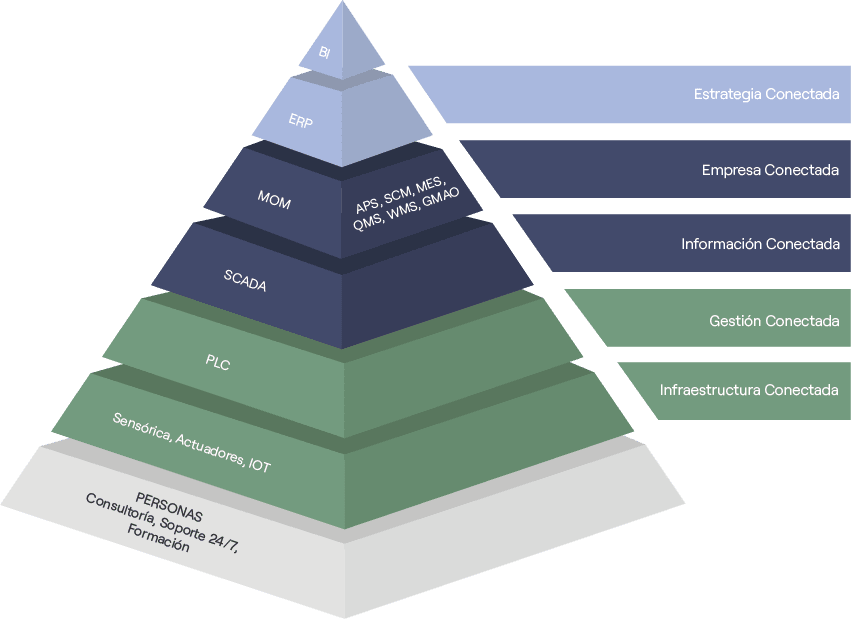

Within the well-known CIM pyramid, the MES system is positioned between the ERP and the shop floor of the factory (PLCs, AGVs, robots, machines, operators, SCADA, etc.). It is the key technological tool in Industry 4.0 and factory management due to the link it provides between business management platforms and the plant’s IoT hardware and elements.

The core of MES is production and it allows factory departments to make real-time decisions based on data generated by these platforms, which are compiled into fully customized reports with key KPIs such as OEE, number of breakdowns, machine status, production order progress, and sequencing, among others.

What is a MOM System?

It is important to understand how MES platforms fit within the MOM (Manufacturing Operations Management) environment.

At Geprom, we consider that a MOM platform encompasses planning, production, quality, logistics, and maintenance functions. Depending on the client’s needs and process requirements, it may be necessary to work with more advanced systems either independently or by combining functionalities into a single platform.

In short, a MOM platform includes the following systems:

- APS / SCM – Advanced Production Planning

- MES System

- SCADA System

- QMS – Advanced Quality Management Software

- WMS – Logistics Management

- CMMS – Maintenance Management

It is essential that these systems are fully integrable into a single platform. It is common to integrate an MES system with planning, quality, maintenance, and logistics modules capable of evolving into a complete MOM platform for comprehensive operations management.ean totalmente integrables entre sí en una única plataforma. Suele ser habitual integrar un sistema MES con módulos de planificación, calidad, mantenimiento y logística capaces de crecer y evolucionar en una única plataforma hasta disponer de una plataforma MOM completa de gestión integral de las operaciones.

Differences and Relationship Between MES and MOM

Is an MES system the same as a MOM system?

No. Although closely related, they are not the same. The MES (Manufacturing Execution System) focuses on managing and controlling production on the shop floor, while MOM (Manufacturing Operations Management) has a broader scope that also includes planning, quality, logistics, and maintenance. In other words, MES is the operational heart of a MOM platform, which integrates multiple functional areas.

What does a MOM system include in addition to MES?

A MOM solution incorporates, in addition to MES, other fundamental modules for comprehensive industrial operations management, such as:

- APS / SCM – Advanced Production Planning

- QMS – Advanced Quality Management

- WMS – Warehouse and Logistics Management

- CMMS – Computerized Maintenance Management

- SCADA – Real-time process monitoring

These systems can be implemented independently or combined in a single platform according to the needs of each factory.rse de forma independiente o agruparse en una plataforma única, según las necesidades de cada fábrica.

When to implement an MES and when a MOM?

An MES system is the ideal entry point for companies seeking to control and digitalize production. However, when complete and integrated operations management is desired, MOM is the appropriate solution. Evolution toward a MOM environment is usually progressive, starting from MES and incorporating additional modules as the factory’s digital maturity increases.

Benefits of integrating an MES-MOM model

- Real-time global operations view

A MES-MOM platform centralizes all production, quality, maintenance, and logistics data, offering a complete and up-to-date view of the plant’s status. This allows teams to anticipate issues, optimize resources, and make data-driven decisions. - Improved plant decision-making

Access to key KPIs such as OEE, order progress, downtime, or machine status enables plant managers to respond quickly and improve operational efficiency in real time. - Alignment with industrial digitalization strategies

Implementing an MES-MOM model is a key step toward Industry 4.0. It connects machines, people, and systems, facilitating automation, predictive analysis, and continuous improvement in all processes.

Which modules are part of an MES-MOM system?

- Production

Control and execution of manufacturing orders, real-time monitoring of line status, equipment efficiency (OEE), and traceability of the entire production process. - Quality

Advanced management of quality controls, non-conformities, automated checklists, integration with laboratories, and digital records to ensure standards and compliance. - Maintenance

Planning and tracking corrective, preventive, and predictive maintenance tasks through fully integrated CMMS systems connected to production. - Internal Logistics

Efficient management of material flow, warehouses, and internal movements through WMS modules connected to production and planning. - Traceability and real-time control

Complete tracking of the product from raw material to finished product, with real-time monitoring through SCADA, sensors, and integrated systems.

Examples of MES-MOM System Applications

Food Industry

Full batch traceability, temperature and production condition control, compliance monitoring (IFS, BRC), and integrated quality and maintenance management to prevent cross-contamination.

Automotive Industry

Tracking the progress of production orders on assembly lines, quality control at each station, integration with VIN traceability systems, and predictive maintenance of critical equipment.

Chemical Industry

Precise recipe management, real-time monitoring of critical parameters, integration with quality labs, and compliance with safety and traceability regulations.