Implementation of the MES Objective system in ScioTeq

Challenges and Solutions

Challenge

- Improve the company’s overall competitiveness in the market by integrating software that would allow them to plan, control and manage production and operations digitally.

- Reduce high costs due to administrative errors, non-compliance with standard processes, quality problems, etc.

- Reducehighcosts duetoadministrativeerrors,non-compliancewithstandard processes, quality problems, etc .

Solution

- Conducting consulting sessions to identify the scope of the project in the field of Industry 4.0 and the linkage of the MES system with their current processes and ERP system.

- Complete integration of the MES Objective System. From data capture on the plant floor to fault and downtime detection and automatic OEE control.

Results

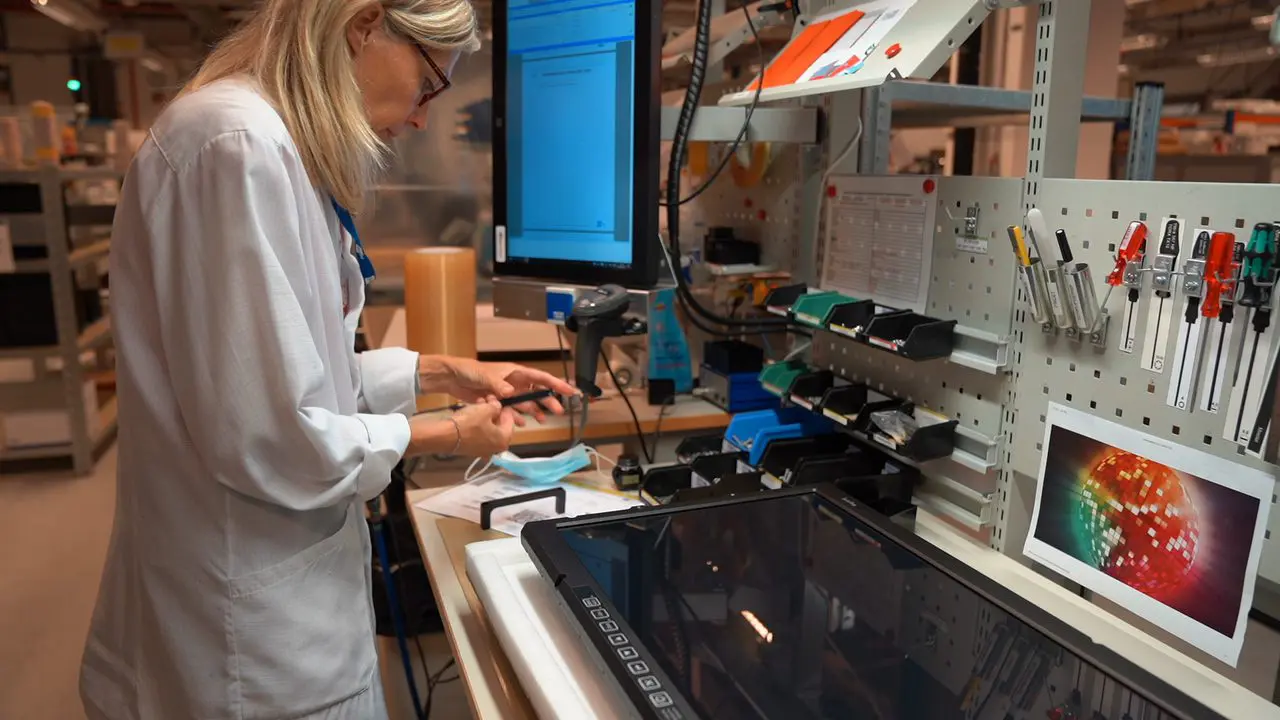

- Information available on screens and PC panels in real time of the production process: Work instructions, manufacturing orders, information on materials and components, register of non-conformities, etc.

- Thanks to the interaction with the ERP all design changes, instructions and due dates are immediately passed on to the operators and supervisors on the production floor.

- In-plant data capture with high availability of reliable data and production monitoring.

- Digitization of production and greater quality control of operations.

- Dashboards and customized reports based on the production department.

testimonial

“At ScioTeq we have a bright future ahead of us. Partly due to the integration of Mes Objective into our operations management.”

Tom Van Canegem

Gerente de fabricación